Density, bulk, whiteness – the main characteristics of paper

The number of types and grades of paper in the modern world is enormous.

The following types of paper are most often used in printing:

– newspaper;

– offset;

– coated;

– book and magazine;

– packaging waste cardboard;

– designer paper and cardboard.

A special type of offset paper is used for copying and printing equipment. Depending on the type of printing (laser or inkjet, color or black and white, low or high speed printing, etc.), you need to use the appropriate paper to get a high-quality print and not damage the equipment.

Special papers for color laser printing are becoming increasingly popular due to the development of digital printing.

Main characteristics of paper: density, bulk, whiteness

.

Additional characteristics: hardness, smoothness, opacity, tensile strength and many others.

Density

measured in grams per square meter. So, for example, an A4 sheet is one sixteenth of a square meter, so with a density of 80 g/m2 it will weigh 5 grams.

To find out how many sheets of a particular paper are in 1 kg, you need to divide 1 by the weight of one sheet. So in 1 kg of paper with a density of 80 g/m2 there are 200 sheets of A4 (1 / 0.005).

Knowing the cost of paper per kg (ton), you can calculate the cost of one sheet using the table below. And vice versa.

Why is paper density not measured in grams per cubic centimeter? The fact is that the density of paper in g/cm3 is close to 1 (the density of water). Therefore, the density indicator in g/m2 is very close to the thickness of the paper sheet, expressed in microns. In fact, when we talk about density, we mean the thickness of the paper. You need to know the thickness of the paper to be sure that it will fit into a particular printing equipment. You also need to know the density to calculate the cost. By introducing the density indicator per square meter, we killed two birds with one stone: one indicator is used both to calculate the cost and to characterize the thickness.

This was the case before, but technology is improving, and manufacturers have learned to make both very loose paper and very thick paper.

It was necessary to introduce one more characteristic – plumpness

. Plumpness is measured in cubic centimeters divided by grams (this is simply the reciprocal of bulk density, which is what you learn in school).

If the bulk density of paper is less than one (lighter than water), its bulk is greater than one, and the numerical value of the thickness in microns is greater than the numerical value of the density in g/m2.

For example, offset and xerox papers with a density of 80 g/m2 have a bulk density close to 1.25. Multiplying 80 by 1.25, we get a sheet thickness of approximately 100 microns. A pack of 500 sheets will have a thickness of 50,000 microns = 50 mm = 5 cm.

Coated papers, on the contrary, have a bulk density of less than one (heavier than water).

How to use it? The price range for paper is very wide. If we talk about the final product, then, from the consumer’s point of view, plumpness and rigidity are important, not density. This makes it possible to replace one type of paper with another in order to reduce the cost of the final product. For example, we will replace paper No. 1 with paper No. 2. Let the bulk of paper No. 2 be 30% more, and the price per kilogram be 15% more. Then we will get a saving of approximately 15%! The effect of using plump papers is especially noticeable in book production, because… The weight of the circulation can be measured in hundreds of kilograms and tons.

Sometimes the reverse replacement is also possible. For example, for laser printing, you can replace paper and reduce bulk by 30% and price by 60%.

From whiteness

paper depends on how contrasting the image printed on it will look and how accurately the colors will be reproduced.

There is an ISO standard for brightness that determines what percentage of light will be reflected when paper is illuminated with light at a wavelength of 457 nm. However, the subjective perception of whiteness by the human eye depends not only on the amount of reflected light, but also on its quality. Perception is affected by the roughness of the surface, the shade of white paper (bluish, yellowish), as well as the presence of optical brighteners in the paper, which, absorbing ultraviolet light, re-emit in the visible spectrum. The CIE whiteness index is closest to human perception and can take values greater than 100%. This indicator is measured in natural sunlight (or close to it, but necessarily containing ultraviolet rays in its spectrum).

Opacity

– this is an indicator of how much the paper itself prevents the transmission of the printed image applied from the back side of the sheet to its front side. This indicator is especially important for double-sided copying, when printing is applied on both sides of a sheet of paper.

Gloss

– this is a characteristic of the mirror reflection of the light incident on it by the surface of the paper. Highly glossy papers have a rate of 75-80%, and matte papers – up to 30%. And, although most consumers of printed products prefer glossy papers, they are not always needed in publications. Thus, when reproducing text or line illustrations, paper with minimal gloss is used, and various brochures, labels, and reproductions of paintings are perfectly produced on high-gloss paper.

Humidity is a very important indicator for laser printing. Typically, office papers are produced with a lower moisture content (4.2 to 4.5%) than offset paper (5.0 to 5.5%). The reason is that office papers are exposed to significant heat in almost all models of copiers. When humidity is low, paper is less exposed to temperature changes and, as a result, is less likely to curl or wrinkle during the transfer process.

Smoothness (roughness)

The geometry of the paper surface is characterized by its smoothness or roughness.

The “surface geometry” of paper is determined not only by micro-irregularities, but also by macro-irregularities. The former are determined by microgeometry, the latter by the distribution of mass over the area.

There is a group of most common methods in which smoothness is measured using air flow.

The most common measurement methods are the Bendtsen Sheffield and Parker apparatus (roughness). Becca (smoothness).

The essence of the Beck method is to measure the time required for air of a certain volume to pass into a vacuum chamber between the surfaces of the test sample and a polished glass plate of a certain area, pressed with a certain pressure. Smoothness is measured in seconds. The higher the smoothness, the greater the value of the indicator.

There are no strict relationships between the values of smoothness (roughness) indicators measured by different methods. There is a qualitative relationship between the Beck smoothness and Bendtsen roughness values.

Bendtsen and Sheffield instruments measure the flow of air passing at constant pressure between the surface of the ring and a sheet of paper.

Bendtsen roughness is expressed in ml/min, Sheffield in Sheffield units.

The figures show qualitative relationships between parameters determined by different methods. They make it possible to evaluate the nature of changes in one parameter depending on changes in another and can help in comparing the smoothness and roughness of samples measured by different methods.

The Parker method (PPS) is used to measure the roughness of paper and cardboard under conditions similar to those of a printing press. The Parker roughness measurement result is expressed in microns.

GOST 9095-89 printing paper. technical specifications dated June 22, 1989 –

GOST 9095-89

Group K61

OKP 54 3121, 54 3122

Valid from 07/01/90

until 07/01/95

in part of paper No. 2

grade B – until 01/01/93*

_______________________________

* Validity limit removed

Resolution of the State Standard of Russia dated 1993 N 4.

(IUS No. 4, 1994). – Note “CODE”.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR Ministry of Forestry Industry, USSR State Committee for Publishing, Printing and Book Trade

PERFORMERS

D. U. Tovstoshkurova, T. K. Okuneva, V. I. Listratenko, Ph.D. tech. sciences; V. A. Zagorsky

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee for Standards N 1824 dated 06/22/89

Date of first inspection – 1993

Inspection frequency – 5 years

3. IN REPLACEMENT GOST 9095-83

and GOST 7317-78

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

This standard applies to paper intended for printing text and illustration-text publications using letterpress printing.

The standard establishes requirements for printing paper produced for the needs of the national economy and export.

1.1. Paper must be manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

1.2. Main parameters and dimensions

1.2.1. Paper must be produced in the following numbers and grades: N 1 grades A, B; N 2 grades A, B, C;

N 1 grade A – 100% bleached cellulose;

N 1 grade B – no less than 80% bleached sulphate pulp, no more than 20% bleached wood pulp;

N 2 grade A – no less than 50% bleached cellulose, no more than 50% bleached wood pulp;

N 2 grade B – no less than 25% bleached cellulose, no more than 75% bleached wood pulp;

N 2 grade B – no less than 50% bleached cellulose, no more than 50% white wood pulp.

The purpose of the paper is given in Table 2 of the Appendix.

1.2.2. Paper must be produced in rolls and sheets.

The width of the roll, the dimensions of sheet paper, maximum deviations in size and slant of sheet paper must comply with GOST 1342

.

1.2.3. The roll diameter should be (850±50) mm. By agreement with the consumer, it is possible to produce paper rolls of other diameters.

1.2.4. Examples of symbols

printing paper N 1 grade A, paper weight with an area of 1 m 48 g, machine smoothness (MG), with optical brightening agent (OBS):

Paper N 1 A 48 MG OOV

GOST 9095

The same, N 2 brand B with a weight of paper with an area of 1 m 60 g, calendered (K), without optical brightening agent:

Paper N 2 B 60 K

GOST 9095

1.3. Characteristics

1.3.1. In terms of quality indicators, printing paper must comply with the standards specified in Table 1.

Table 1

Indicator name | Paper Standard | Test method | ||||||||

N 1 | N 2 | |||||||||

A | B | A | B | V | ||||||

1. Mass of paper with area 1 m, g | 48.0±2.0 60.0±2.0 65.0±2.0 70.0±2.5 80.0 ±2.5 | 65.0±2.5 | 60.0±2.0 | 60.0 ±2.0 | 60.0±2.5 | According to GOST 13199 | ||||

2. Density, g/cm of machine smooth paper: | According to GOST 27015 | |||||||||

for a mass of paper with an area of 1 m 48 g | 0.70-0.80 | – | – | – | – | |||||

for a mass of paper with an area of 1 m 60-80 g | 0.75-0.85 | 0.75-0.85 | 0.70-0.80 | – | 0.65-0.75 | |||||

calendered paper: | ||||||||||

for a mass of paper with an area of 1 m 48 g | 0.80-0.90 | – | – | – | – | |||||

for a mass of paper with an area of 1 m 60-80 g | 0.85-0.95 | 0.85-0.95 | 0.80-0.90 | 0.70-0.80 | 0.75-0.85 | |||||

high calendered paper | 0.95-1.05 | – | – | – | – | |||||

3. Breaking length on average in two directions, m, not less | 24….0* | 2500 | 2200 | 2200 | 2000 | According to GOST 13525.1 | ||||

________________ * Defect of the original. – Note “CODE”. | ||||||||||

4. Fracture strength with multiple bends in the transverse direction, number of double bends, not less: | According to GOST 13525.2 | |||||||||

paper No. 1 on a device with sample tension (9.80±0.20) N: | ||||||||||

for a mass of paper with an area of 1 m 48 g | 3 | – | ||||||||

for a mass of paper with an area of 1 m 60-80 g | 4 | 5 | – | – | – | |||||

paper N 2 on a device with sample tension (4.90±0.10) N | – | – | 10 | 10 | 7 | |||||

5. Mass fraction of ash, % | 16-20 | 16-20 | 12-16 | 10-14 | 16-20 | According to GOST 7629* and clause 3.4 of this standard | ||||

_________________ | ||||||||||

6. Smoothness, s, paper: | ||||||||||

According to | GOST 12795 | |||||||||

| with optical brightening agent | 85.0-88.0 | 80.0-83.0 | ||||||||

without optical brightener | 78.0-82.0 | 76.5-79.5 | 74.0-77.0 | 70.0-72.0 | 66.0-70.0 | |||||

9. Opacity, %, no less: | According to GOST 8874 | |||||||||

for a mass of paper with an area of 1 m 48 g | 93 | – | – | – | – | |||||

for a mass of paper with an area of 1 m 60 g | 94 | |||||||||

| 5.5±1.0 | 6.0 | |||||||||

6.0±1.0 | According to GOST 13525.19* | GOST 13525.19-91 | ||||||||

| Temperature, 0 C | Relative humidity, % | Mode characteristics |

| 23±1 | 50±2 | Conditioning conditions for most printed papers |

| 27±1 | 65±2 | For tropical conditions |

| 20±1 | 65±2 | For special conditions |

The samples are kept until they reach equilibrium moisture content, which is considered achieved if, with two consecutive weighings of the sample carried out after 1 hour, the last mass differs from the previous one by no more than 0.25%.

When storing and testing samples, the equilibrium humidity should not change (GOST 13523–78. Method of conditioning samples).

Example: difference between cardboard and paper 300 g/m2

- cardboard contains coarser and larger fibers than paper;

- cardboard with the same mass per square meter is thicker – paper is no thicker than 0.25 mm, cardboard is 0.3-0.5 mm;

- cardboard has a layered structure, the inner layers can be made from a coarse, cheaper fraction of fibers;

- cardboard is stiffer;

- paper contains more sizing and its surface is (almost always) smoother.

FAQ ➤

Difference Between Kraft Paper and Kraft Cardboard

As mentioned above, the main difference is in the structure. Paper is homogeneous (with the exception of a possible surface coating – coating, for example), cardboard is multi-layered and/or contains thicker and longer fibers of cellulose and wood pulp. Therefore, cardboard of the same weight as paper will be much stiffer and stronger.

Both kraft paper and cardboard can be either ordinary, for mass consumption, or designer. Designer ones are distinguished by a more uniform structure and a “noble” external texture. Kraft paper and kraft cardboard are used in cases where it is necessary to ensure high strength and better moisture and grease protection of the packaging. Designer varieties are used to emphasize the unusualness of the product and the manufacturer’s commitment to protecting the environment – such an environmental fashion.

As you can see in the photo below, kraft cardboard sheets are more rigid than paper, the sheets hold their shape well and do not sag. When kraft cardboard is torn, a layered structure is visible, while the paper structure is homogeneous.

Tensile strength (tear resistance)

Tensile strength is characterized by breaking force, tensile strength, tensile strength index, breaking load, breaking length and is determined according to GOST 13525.

1 “Semi-finished fibrous products, paper, cardboard. Methods for determining tensile strength and tensile elongation”, according to ISO 1924/1 “Paper and cardboard. Determination of tensile strength.” The method consists of stretching a strip of a test sample of a certain size, the ends of which are fixed in clamps, until it breaks at a constant rate of increasing the distance between the clamps.

When determining tensile strength characteristics, strips of paper 15 mm wide, standard lengths, most often 180, 150 mm, are tested on a tensile testing machine.

Breaking force is the force required to break a strip, divided by its width.

Tensile strength represents the tensile strength divided by the cross-sectional area of the specimen.

The magnitude of the breaking load is the force at which the test strip breaks.

The tensile strength index is calculated as the ratio of the tensile strength to the weight of paper with an area of 1 m2.

Breaking length is the conventional length, expressed in meters, of a strip of paper (cardboard) that breaks under its own weight when suspended vertically at one end.

Sizes of rolls, sheets, braids

The dimensions of paper sheets (paper format) and the width of rolls are determined using a metal ruler and a metal tape measure (GOST 21102).

The width of paper and cardboard in rolls is determined by measuring the width of sheets taken from the roll.

For sizes up to 1 m, measurements are made with a metal ruler, for sizes over 1 m – with a metal tape measure.

Measurements using a ruler and tape measure are made with an accuracy of 1 mm.

Sheet and roll paper sizes are standardized.

GOST 9327 “Paper and paper products. Consumer Sizes” defines standard sheet paper sizes.

According to GOST 29314 (ISO 478), ISO 593, the following formats are established:

- roll width: 43, 45, 64, 86, 90, 122, 128;

- uncut sheet sizes: 90 x 128;

- uncut sheet sizes: 86 x 122;

- uncut sheet sizes: 64 x 90;

- uncut sheet sizes: 61 x 86;

- uncut sheet sizes: 45 x 64;

- uncut sheet sizes: 43 x 61.

According to GOST ISO 217‑2021, the sheet format is designated by two sizes in millimeters. The format can also be supplemented by indicating the direction of cutting the sheet using the letters: LG and SG.

The first sheet size refers to the side perpendicular to the machine direction, the second size refers to the side parallel to the machine direction. Thus, the format of a sheet of longitudinally cut paper with dimensions of 430×610 mm is designated as 430×610 mm LG, and a cross-cut sheet is designated as 610×430 mm SG.

Slitting paper (LG) is a sheet of paper whose long side is parallel to the machine direction.

Cross Cut Paper (SG) – A sheet of paper whose short side is parallel to the machine direction.

The above is illustrated by the picture.

Production tolerances for formats are established by agreement between trading partners.

Cutting sheets of paper, i.e. the degree of mismatch between the sides when bending sheets is determined according to GOST 21102–97.

Characteristics of sorption properties

Being a capillary-porous colloid, paper is in an unstable dynamic interaction with the surrounding moisture, absorbing or releasing water, tending to an equilibrium moisture content under given conditions.

The sorption properties of paper in relation to oil are also important to characterize its interaction with printing inks.

The property of paper is also known as hydrophobicity, which characterizes its tendency to be wetted by water. The higher the hydrophobic properties of paper, the more difficult it is to wet with water. A characteristic of short-term hydrophobicity is the paper sizing indicator.

The degree of sizing characterizes the ability of the ink to blur when writing with a fountain pen, giving so-called “whiskers” when writing a line instead of a clear edge line. The method is not used often and is replaced in paper standards by the Cobb absorption method.

To a certain extent, at a constant mass of 1 m2, hydrophobicity is assessed by the absorption of water during unilateral wetting for 20, 60 seconds or for another time on a Cobb device (GOST 12605).

The same device can also be used to determine the amount of oil absorption, however, it does not correlate well with the conditions of the printing process, therefore, to determine the amount of oil absorption, it is better to use tests on the IGT proof printing machine discussed earlier.

At the same time, it should be borne in mind that for materials that do not absorb oil well, the method must be modified and the time for the disappearance of the shiny trace of a drop of oil on paper to be determined.

The tendency of paper to absorb water can be characterized by its equilibrium humidity at a certain relative humidity and ambient temperature, and which is determined by the amount of weight loss of a paper sample when dried to constant humidity (GOST 13525. 19).

When intaglio printing with toluene-based inks, the indicator of paper absorption by xylene is important, which is currently used to assess the interaction of paper in general with organic solutions (GOST 12603).

How does “inkjet” photo paper differ from “laser” paper

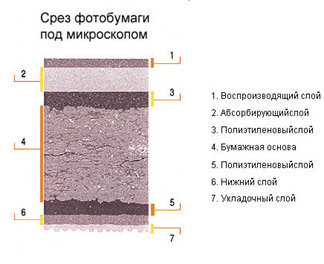

Photo paper for inkjet printers is multi-layered: each layer is responsible for its own section of work to create a print. From image formation – absorption of ink, its correct distribution, drying and transmission of a given color, to consumer characteristics – durability, light and water resistance, the ability to feed into the front and rear tray of the printing device.

The top microporous layer has a sensitive coating designed to properly distribute the ink, preventing it from bleeding and mixing. This coating contains a variety of components, including aluminum oxide, quartz, clay, titanium dioxide, calcium carbonate and various polymers, which enhance adhesion to ink, provide a wide color gamut, low absorption of ink into the base, high brightness, etc.

Following them comes the paper base – the thickest layer, consisting of cellulose. It determines the density of photo paper and its whiteness. In high-quality papers, the cellulose base is enclosed in two layers of polymer on both sides (“Resin Coated” or RC paper). This paper is more durable – it is less susceptible to fading, moisture and oxygen, curls less and is more durable.

The bottom layer is a dense substrate responsible for strength and maintaining the correct shape of the carrier over time. The laying layer serves to apply all of the above layers, sometimes branded.

“Laser photo paper” is produced using a different technology: the paper consists mainly of wood containing cellulose fibers and a natural glue – lignin. Such paper is impregnated with a special resin to increase density and is calendered, that is, ironed between two hot metal press rolls.

Laser photo paper absorbs ink much worse (much worse than regular office paper!). But the hot toner powder “sticks” perfectly to its surface. By the way, using photo paper for inkjet printing in a laser printer will also not give a good result and may even damage it: due to heating, the glossy coating can peel off along with the toner and damage the printer mechanisms due to high printing temperatures.